A significant effort goes into engineering an effective plastic injection mold design. Experienced engineers pore over the design and then conduct an analysis to ensure the tooling will function as intended during production. Maintaining the high performance level for which the tool was designed is essential, especially when you’ve invested time and funds into plastic injection molding and quality engineering. Preventive maintenance is a key part of the equation.

At Reliant Plastics, our services extend beyond plastic mold design to maintenance and servicing. With an in-house tool repair shop, we provide our customers with extensive support to keep their production runs at the highest quality. Fully equipped and ready to work, our in-house tool repair facility enables us to perform critical maintenance, repairs and work as needed.

Preventive Maintenance Reduces Downtime

As molds run through each production cycle, they’re subjected to immense pressures and high heat levels. Despite being made of highly durable metal materials, wear and tear occurs over time. Without proper monitoring and maintenance, problems may develop. For example, areas of irregular temperature distribution could cause deformation or defects in the plastic product. A product may not cool all the way and could fail to eject from the mold or leave behind residue that affects the following product. Inspection and maintenance can help.

Likewise, easy access to tool repair ensures you can minimize downtime caused by production problems. If a mold fails, it can be very costly to correct the problem quickly. Catching issues early and conducting effective repairs is always better than trying to rectify failures after the fact.

In-House Tool Repair Shop Ensures Cost Savings, Improves Productivity, and Customer Experience

At Reliant, we prioritize rapid access to tooling repair and inspection facilities to support our customers. Our climate-controlled tool room spans 5,000 square feet and provides the ideal workspace and conditions for maintenance. When work is necessary, we can spring into action quickly.

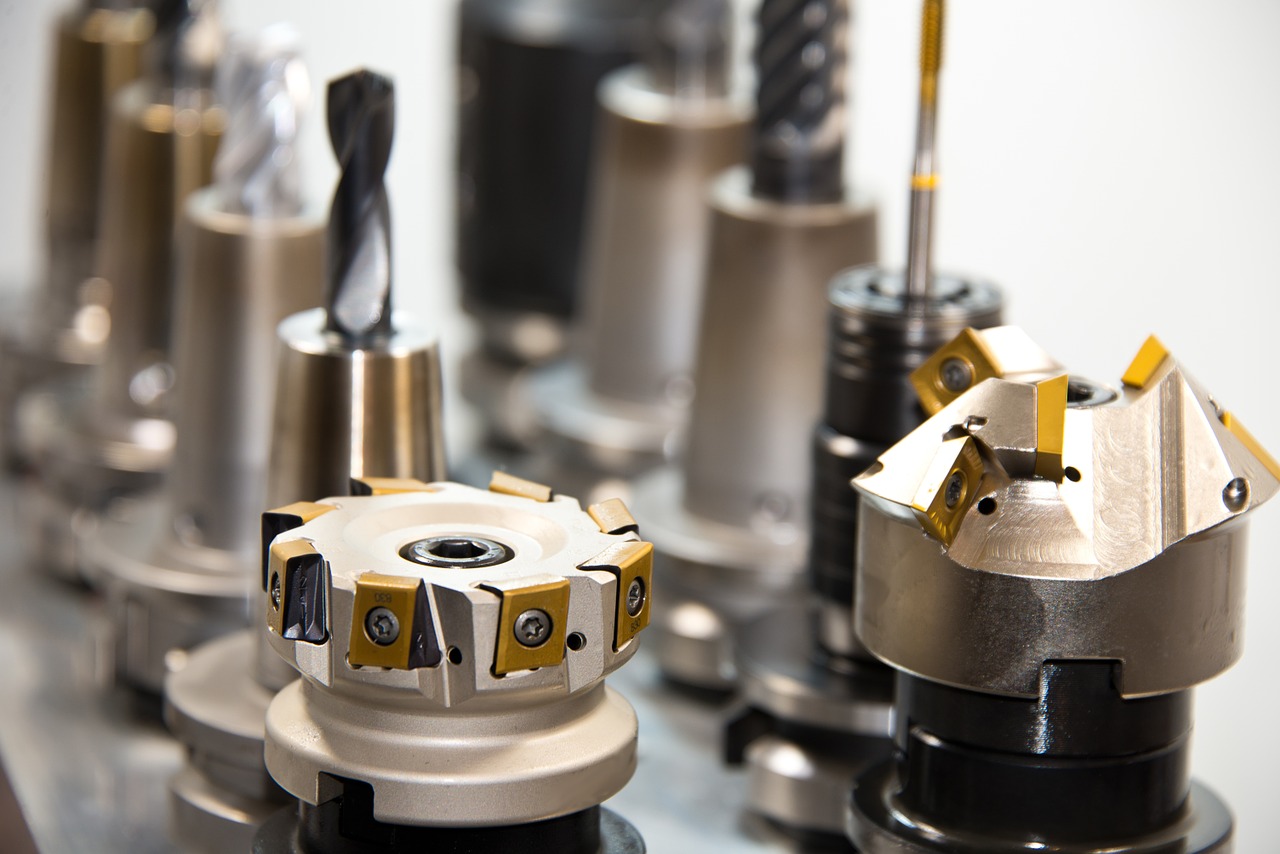

Tool room equipment includes all the lathes and mills necessary to adjust or repair molds. Here, we also conduct detailed inspections of parts and examine them for emerging signs of wear. Periodic preventive maintenance extends mold lifetimes and safeguards the value of your investment. We continually refine our techniques and maintain a variety of cutting-edge equipment to deliver excellence in this space.

With access to our repair facility, customers can enjoy numerous advantages compared to other typical industry arrangements. Team experts can resolve issues discovered during molding more quickly and without needing shipment to an off-site location. This creates several key benefits for our customers, including:

- Cost savings. Repairs or maintenance are more accessible and do not involve additional expenses beyond the work inside the tool shop.

- Decreased downtime and increased productivity. When a mold comes offline promptly, quick action can return it to service.

- Rapid repairs. Critical repairs take place in a shorter turnaround time.

- Personalized customer service. Customers connect directly with our team and get clear communication about maintenance, repair work, and corresponding timelines..

- Expert guidance. Our team’s insights help clarify and correct production runs that don’t meet the desired standards.

Discover How Reliant Plastics Can Support Your Injection Molding Projects

After pouring so much time and effort into obtaining the right injection mold tool design, ensure that your investment pays dividends for the foreseeable future by working with Reliant Plastics. When things go wrong, proper preventive maintenance and help from an experienced molding engineer protect your projects. When you don’t need to package tooling for shipment to far-away factories overseas, you can place your trust in a proven domestic team capable of the faster turnarounds you require.

We’re proud to back up our plastic injection mold design services with our in-house tool repair facilities. We stand by our work and strive to ensure that your production projects stay on target even when maintenance issues arise. Speak with our team today to learn more about how we can store and maintain tooling for your critical components.