In manufacturing, few topics have generated as much buzz and interest over the past decade as 3D printing. Also known by its technical name, “additive manufacturing,” 3D printing is often described as a revolution. So what makes this technology so interesting, and where does it fit into the big picture of manufacturing solutions? Ahead, we break everything down, along with how it compares to the gold standard, plastic injection molding.

3D Printing, Defined

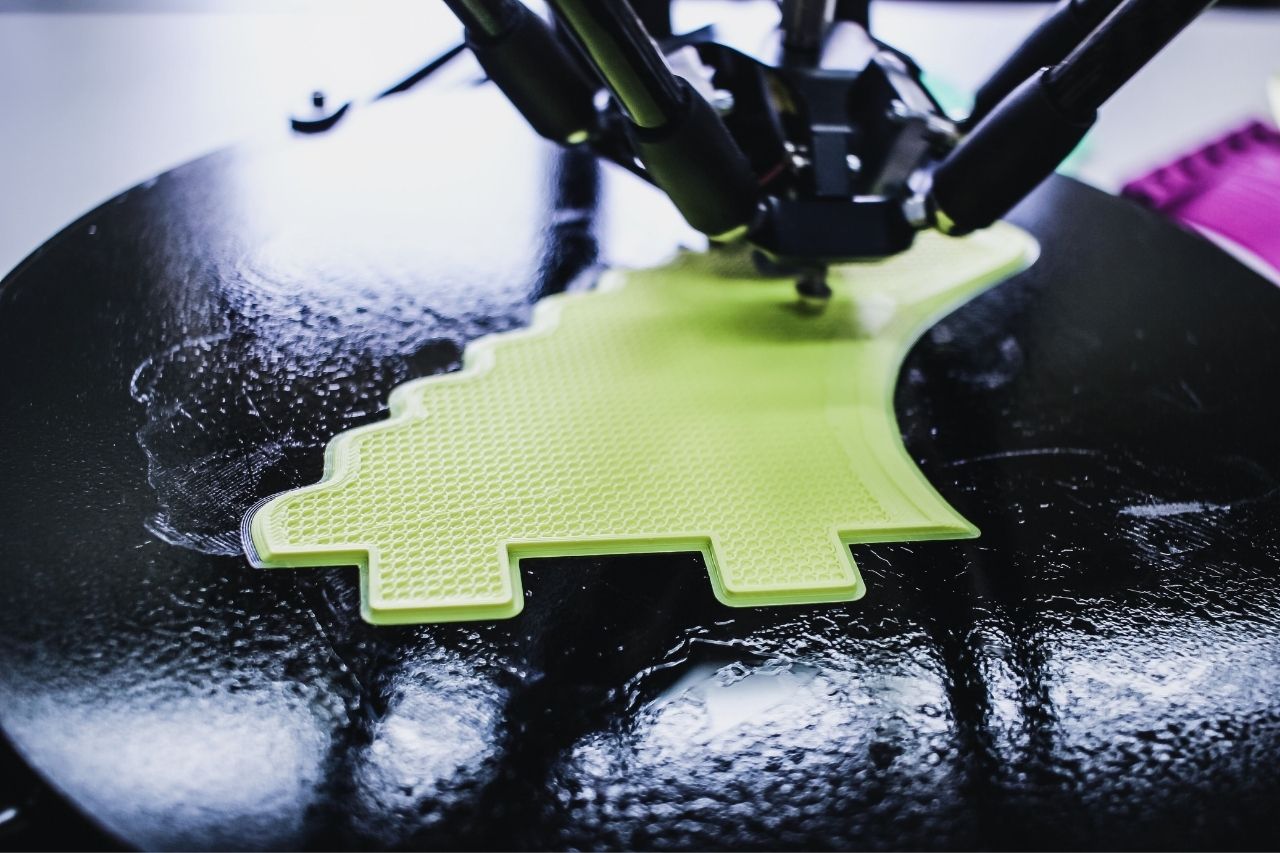

3D printing begins with a 3D design file created on a computer. As with CNC machining, this file tells the 3D printer how to behave when creating the object defined by the file. With these metrics, the printer uses a plastic filament and heating element to deposit successive layers of plastic, one after another. Each layer is a cross-sectional slice of the item under production. Over the course of a print run, the machine proceeds layer by layer to build the entire object from bottom to top.

Injection Molding, Defined

Similar to 3D printing, injection molding involves the injection of molten plastics into a mold. A mold also starts its life as a computer file to validate the design before manufacturers create mold tooling out of steel or aluminum. Injection equipment — a hopper and screw — heats the raw plastic material to its melting point before forcibly injecting the molten mix into every part of the mold cavity. When the plastic cools and cures sufficiently, the mold opens to eject the part before the cycle starts again.

Differences Between 3D Printing and Injection Molding

In terms of method, these two manufacturing options are fundamentally different from each other. And though there are several significant variances to note, the two technologies diverge the most in three specific areas.

Manufacturing Costs

Injection molding has comparatively high upfront costs. You must design the mold tooling to create each part and then validate that design. Tool production can also be a big investment. Once you have the tooling, your costs primarily relate to materials and mold operation time. Prices per part are very low in high-volume production runs.

On the other hand, one of the benefits of 3D printing is its relative lack of upfront costs for tooling. You create the design entirely in a digital environment. However, the price per part is much higher with 3D printing due to the singular nature of each print job. With this method, only one item is printed at a time, which drives costs up when 3D printing many items.

Production Time

Production times are short once an injection mold tool is ready for work. Multiple machines simultaneously running the molds can produce thousands of parts a day, as most of the production time in injection molding occurs near the beginning of development. During actual production, products are acquired rather quickly.

3D printers continue to get faster, but they’re not as quick as popping parts out of a mold. Complex designs can take hours or even days to fabricate with a 3D printer. But there is an upside: Since you can create a digital model for printing more quickly, you can have a prototype in hand much sooner than you otherwise could.

Product Consistency

Injection molding is excellent for products that need to be as identical as possible with every single production run. You won’t have a high failure rate if you control conditions within the mold and correctly manage cooling. Consistent outcomes are a major reason for injection molding’s popularity.

Depending on the hardware used, 3D printing is more likely to involve slight variations from item to item. A print can also fail in the middle of a production run, often due to a jammed print head. Consistency is achievable with 3D printing, but it requires greater care.

Use Cases for Different Manufacturing Methods

Although 3D printing and injection molding share similarities in the materials they use, their method of using that material leads to different outcomes. While you could use injection molding to make some 3D-printed objects, it would take time and money to create the tooling. Similarly, you might use 3D printing to create a design similar to an injection molded part. However, at the end of the process, you’d still have only one of the parts — not the high-volume injection molding results. With that in mind, let’s explore how the applications for these methods differ.

Common Applications for 3D Printing

Popular with hobbyists, 3D printing also has an array of applications at the industrial level. Some of the most common 3D-printing applications:

- Produce difficult or impossible designs with injection molds, such as components with open sections or very complex geometry.

- Produce prototype designs. With no need to build mold tooling, 3D printing allows cost-effective testing proofs of concept. One-off prototypes offer a more cost-effective way to validate designs.

Advantages of 3D Printing

Why do businesses invest in 3D printing over a more traditional route for manufacturing? There are two key benefits of 3D printing that showcase why it is the right choice for specific projects.

- Low Initial Costs. Designing 3D printing parts is comparatively less complex than injection molding. All design takes place on a computer, and there is no need for an intermediate production step before manufacturing can start. Plus, 3D printing equipment is usually cheaper than molding machines.

- High Flexibility. Iteration is straightforward on a 3D-printed design — modify the print file and start again.

Disadvantages of 3D Printing

As a relatively new technology, 3D printing has some intrinsic limitations and concerns that can constrain its usefulness in specific contexts. When considering the usefulness of this manufacturing technique for a project, keep the following disadvantages of 3D printing in mind.

- Technical Issues. 3D printers, especially some commercially available units, can run into printing issues that cause extended production times. For example, it is possible for the filament to prematurely harden in the print head, causing a jam that requires manual cleaning.

- Inconsistent Product Quality. Due to issues with the printing process, it’s not always possible to guarantee consistent quality from print to print. 3D-printed objects also tend to have rougher, more unfinished surfaces.

- A Slower Process. Large printing projects can take 24 hours or more to complete, sometimes even several days, to create one part.

Common Applications for Plastic Injection Molding

As one of the world’s most popular and widespread manufacturing solutions, injection molded items are easy to find everywhere, from the workplace to the home. Some of the most common applications for injection molding include the creation of parts and components for:

- Projects that demand high volume over long production cycles, potentially tens or hundreds of thousands of parts.

- Products that require specific properties of plastics, such as food safety qualities or chemical resistance.

- Products that require a very smooth and polished finish, which is not always possible with plastic 3D printing.

Advantages of Injection Molding

With a history that goes back decades, injection molding is a more entrenched technology than 3D printing. It also provides users with core benefits that make it an advantageous choice in many contexts.

- Low Unit Costs. Most of the significant expenses related to injection molding stem from the cost of creating and maintaining molds. Once built and validated, molds produce parts for a long time, driving down costs per unit.

- High Quality. Properly maintained molds can produce the same-quality parts again and again, today or a year from today. When projects demand consistent quality, injection molding achieves it with ease.

- Fast Manufacturing. Cycle times with injection molds are orders of magnitude faster than 3D prints, and it’s possible to arrange for high-volume production with short lead times.

Disadvantages of Injection Molding

There are some disadvantages of injection molding. As with 3D printing, you should consider the following drawbacks before investing in a project.

- Upfront Investment. The significant cost in injection molding comes from tooling creation. It is a multistep process that requires precision, especially when creating steel molds.

- Modification Limits. Once an injection mold for a product is created, making any fundamental changes to the design is difficult or impossible. Part profiles must undergo extensive validation before going into production.

Explore the Best Solutions With Reliant Plastics

The differences between 3D printing and injection molding don’t mean they can’t complement one another. As the technologies evolve, so does their place in the manufacturer’s toolbox. At Reliant Plastics, it is our job to monitor such evolution and keep the client abreast of their benefits.

Bringing a product to life, from the design stage to manufacturing, requires many steps and the professional input of experienced designers and other professionals. We use our years of industry experience to provide our clients with top-shelf services, including injection mold design and manufacturing. Our extensive capabilities enable the best solutions for your next part production run.

For a free quote or to learn more about our services, contact Reliant Plastics today.