With nearly a century of progress in injection molding, these technologies are fully mature and capable of a great amount of manufacturing tasks. Today, the world consumes a massive amount of plastic annually, and plastics form the backbone of many industries as the primary material of choice. However, not all injection molding processes are the same, just as all the materials in use are not homogeneous.

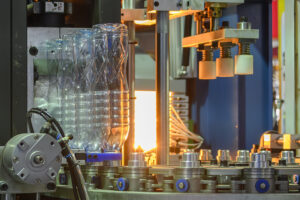

When most people think about injection molding, particularly when designing new components, they imagine the typical process in which hot, molten plastic is injected under pressure into the empty cavity of a mold. Once the plastic cools, it’s ready for removal and the next stage of production. These are thermoplastics, which easily melt under high temperatures and are easy to recycle.

However, there are many applications that call for a hardier, more robust type of plastic that can withstand challenging environments. In these cases, thermosetting plastics are the material of choice. Once these plastics undergo treatment at high heat and cool again, the polymers they consist of undergo a process called “cross-linking.” The result is a permanent plastic matrix that can’t be altered. Naturally, working with such materials presents a new set of challenges. Can you effectively use thermosetting plastics with injection molding hardware?

The Unique Mechanics of Injection Molding Thermosetting Plastics

The answer is “yes,” but with some caveats. The typical injection molding machine based around the screw auger is not suitable for thermoset plastics due to the nature of the materials. If plastic manufacturers use thermoset plastics in the wrong equipment, it could potentially ruin the entire molding machine as the plastic could set up and crosslink inside the actual augering mechanism.

Therefore, specialized hardware is necessary for injection molding with thermosets. These units are typically more expensive and apply unique procedures, such as internal screw thermoregulation, to keep the plastics from attaining their crosslinking temperature until they enter the mold. It is, therefore, possible to take advantage of the benefits of injection molding while using thermoset materials.

What Applications Are Possible with This Technology?

When are thermosetting plastics the right idea? The most common applications for injection-molded thermoset plastics include using cases where the parts must endure high temperatures, repeated exposure to corrosive agents, or other tough conditions. Components for medical devices or in hospital usage often use thermosets due to the intensive disinfection procedures they undergo. The automotive industry also continues to consume a large number of thermosets for high-heat applications. With the appropriate molding technology, though, thermosets open a vast world of possibilities.

Choosing Plastic Manufacturers Capable of Multiple Approaches

Working with thermoset plastics provides more versatility and additional options for solving unique engineering problems. At Reliant Plastics, we offer expertise and years of experience as plastic manufacturers to support clients in diverse industries seeking a reliable solution for thermoset and thermoplastic manufacturing. To further explore the details and logistics of injection molding with thermosets and how they may benefit for your project, send us an inquiry today.