The backbone of plastics production is the injection molding machine. Every year, machines worldwide shape and eject billions of components that flow into every industry. The proper capacity ensures faster results of higher quality, attributes every business hopes to find in its supplier. At Reliant Worldwide Plastics, we already have an extensive equipment family available under one roof. But we’re excited to share that our equipment stable has grown even more extensive.

Reliant is proud to announce an additional acquisition of five new plastic injection molding machines. These additions continue to extend capabilities to our customers and enhance operational efficiency. We now field nine versatile and advanced units, including three 170-ton machines. Ahead, we explain more about these new machines and how they will help Reliant continue to deliver exceptional results.

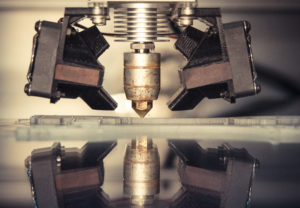

Introducing New Milacron Injection Molding Machine Options

Selecting the right equipment to support our customers is a lengthy process. It involves scrutiny of everything from technical specifications to the ease of repairing or replacing essential injection molding machine parts. Ultimately, we found that our criteria and high standards were best satisfied by the Q-Series molding machines produced by heritage brand Milacron.

Milacron, a subsidiary of Hillenbrand Inc., is a U.S.-based manufacturer of advanced molding machines with decades of history. Beyond enhancing our molding capabilities, we are excited about acquiring equipment from a fellow domestic supplier, further contributing to our “Made in the USA” stamp.

What Machines Have We Added?

Reliant has selected five more machines from the Q-Series to add to the hardware lineup in our manufacturing facilities. This acquisition complements four previous Q-Series purchases. We chose each one because of its versatility, power, and maintenance requirements, among other factors. Our lineup of machines now spans a broader range of maximum tonnage limits, including:

- 125 tons

- 170 tons

- 200 tons

- 260 tons

- 315 tons

- 400 tons

- 610 tons

Tonnage is critical in successful molding projects; correct clamping forces are essential for proper operation and quality output. These units are not only highly advanced in their molding and ejection hardware but are also energy efficient. Overall, the attributes of these machines make them well-suited to the types of projects Reliant handles across industries with strict requirements, such as the automotive and aerospace sectors.

What Capabilities Have We Added?

Between the advanced software powering these new machines and their incredible purpose-built ability for injection molding, we will enjoy several advantages thanks to the Q-Series. We anticipate seeing improvements in areas such as:

Mold changeover time

Faster changeovers produce more varied parts that require specific clamping pressures and molding times.

Mold start-up time

Getting a production run started will become simpler due to improvements in the Q-Series that streamline setting up new molds and configuring the machine for manufacturing.

Component cycle times

We will be able to complete and eject parts at a higher rate with these machines, allowing for the completion of more molding cycles in a shorter period.

Mold wear and maintenance

A specially designed platen ensures equal pressure across the entire mold inside a rigid base. This feature and the design of the unit’s clamp translate into reduced wear and tear on molds, boosting carrying capacity and keeping the mold square.

Part quality

Already a significant focus for our teams, the Q-Series will enable us to achieve even better results on every part. Milacron software enhances unit uptime and helps reduce failures, translating into better and faster results for our clients.

Sustainability

Smart energy usage and sustainable practices are more critical than ever. The Q-Series delivers exceptional performance through one of the industry’s most energy-efficient designs.

Which Industries Do the New Machines Serve?

With three Q-Series 170 units and a range of other clamp tonnages, Reliant has an even greater capacity to serve clients across diverse industries. Manufacturing on these machines works especially well for parts produced for sectors such as:

We can pass along several advantages to our customers through machinery capable of these improvements. Combined, the capabilities of these new machines will let us achieve critical improvements in order and production lead times. With abilities to increase output and produce a higher volume of parts each month, we can speed orders toward fulfillment without sacrificing quality at any step.

Getting Your Next Project Started With Experienced Help

With each machine from the Q-Series, we’ve extended our capacity and improved our ability to deliver fast, effective results for our customers. At Reliant, we support our partners with a flexible and scalable service that adapts to your needs. Our new molding hardware ensures we can continue providing the resources you need to make your project successful.

Reliant offers support through an entire project life cycle or as needed. We provide mold design, testing, and production capabilities alongside injection molding. Combined with our extensive secondary operations, we can be your primary partner for successfully engineering new products and components.

To learn more about our services, contact our team today.