Aerospace has always been a cutting-edge industry. Material selection, quality manufacturing, and precision engineering are central to success in this sector. These efforts ensure that this mode of transportation remains safe and reliable.

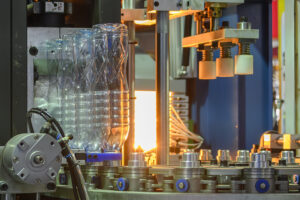

Today, many materials are used to create modern air and spacecraft, ranging from special metal alloys to advanced composites and plastics. The injection molding machine is one of the technologies that has made some of the most significant contributions to aerospace advances. Through thermoplastic injection molding, aerospace industry companies can tap into a wide range of benefits that yield real-world improvements, noticeable cost savings, and better product outcomes.

Aerospace Injection Molding to Meet Engineering Demands

In aerospace, precision and reliability are of the utmost importance — considerably more so than sectors like consumer goods or lawn and garden. The safety of pilots and passengers depends on making the right choices in manufacturing. Even for components that aren’t mission-critical, quality contributes to usefulness and aesthetic appeal. Manufacturers must choose materials that:

- Adhere to tight tolerance requirements

- Withstand challenging environmental conditions

- Meet regulations and best practices for safety in component durability

Plastics are the optimal material in each use case.

What are the most common uses for injection molding in the aerospace industry?

Injection molded plastics are ubiquitous in commercial aircraft and in the aerospace industry Advanced design capabilities and modern thermoplastics enable a more comprehensive range of applications than ever before. Some of the most frequent uses for injection molding in the aerospace industry include:

Interior Components

Plastics are ideal for many of an aircraft’s interior elements, such as interior wall paneling. Overhead compartment doors also often feature molded plastic. Seat frames and armrests may use plastic, as do the seat-back tray tables. Many components of the beverage push-carts used by attendants use plastic. Even the window covers often come from an aerospace plastic injection molder. Hardware inside the cockpit, including the buttons and dials used by the pilots, uses durable molded materials.

Structural and Engineering Components

Operational components with high tolerance requirements may use plastics and include components in heavy-duty, high-wear environments, such as bushings and bearings. Mechanical seals for fuel, hydraulics, oxygen, and other on-board systems may use highly chemical and heat-resistant plastics.

6 Ways Plastic Injection Molding Benefits the Aerospace Industry

Manufacturers choose plastics for these products because they offer essential material advantages. Understanding the benefits these materials create for engineers and builders reveals why the industry relies on plastic, from independent kit makers to principal airline companies.

1. Thermoplastics have a high strength-weight ratio.

Aerospace plastic injection molding services have reached a very advanced level today. Reinforcing popular resin selections with advanced materials such as glass or carbon fiber is now possible. The incredible strength-to-weight ratios achieved through this combination make it a perfect choice for aerospace projects aiming to reduce the reliance on metal components. These resins exhibit remarkable physical properties that make them incredibly durable and reliable. They can meet or even exceed the performance of a metal component.

2. Plastics enable successful lightweighting projects.

Airlines of all sizes prioritize reducing emissions and cutting costs. In this environment, lightweighting projects have become of new importance. Metal-to-plastic transition projects continue growing in popularity due to their high success rates. Modern thermoplastics are incredibly strong and often weigh far less than similar machined parts. These material conversions require careful planning, but the results speak for themselves.

3. Execute complex designs with aircraft injection molding.

Modern computer-aided design makes incredible precision possible today. However, geometric complexity makes some components difficult to machine even with those precision tools. Plastic injection molding for the aviation industry can be more flexible, allowing complex designs from a single mold. Such tooling reliably and rapidly produces parts with complicated geometries and intricate details. Traditional metal machining processes are slow and time-consuming with such projects. These processes can’t keep up with the speed and consistency of aerospace plastic injection molding.

4. Meet demanding aerospace tolerance requirements.

Everything must fit together precisely in aerospace construction. Consistent part production ensures critical safety systems function and achieves general airworthiness and aerodynamic qualities. As a result, meeting strict tolerances has always been a pillar of aerospace manufacturing. When properly designed, tested, and maintained, today’s injection molds can yield tight tolerances accurate to +/- .001 inches.

5. Achieve cost-effective quality across entire production runs.

Molding achieves highly replicable part production. Simultaneously, the capability to fulfill large order volumes enables economies of scale. Raw materials are often less expensive compared to metal. With access to the best aerospace injection molding support, you can count on consistent results across production runs.

6. Scale up to support intense manufacturing demands.

Metal fabrication is time-consuming, especially in precision applications. Producing multiple metal parts simultaneously becomes extremely expensive due to the required tooling and hardware. Conversely, some injection molds can make a dozen or more parts at a time, opening the door to reliably meeting inventory needs. Adjusting production runs is simple and hassle-free as needs grow or shrink.

Advancing Toward the Future of Aerospace With Reliant Plastics

The right industrial partner makes a difference in aerospace and defense industry plastics. Experienced and knowledgeable customer service opens the door to everything from understanding the basics, such as, “What is an injection mold?” to the more in-depth topics, such as, “What resin is best for high-altitude, high-stress applications?”

At Reliant Worldwide Plastics, our decades of experience as an innovator in manufacturing advanced parts make us a proven partner for many aerospace customers. We can connect you with advanced capabilities in injection molding for aircraft and more today. Contact us to learn how we can help.