About Us

Who We Are

Since 1968, Reliant Worldwide Plastics has been one of the leading injection molding providers in the Dallas-Fort Worth area. We specialize in metal-to-plastic conversions with extensive experience across countless projects involving injection molded plastics. We deliver five-star results for even the most complex engineering challenges using innovative design, advanced technology, and modern equipment.

Based in Gainesville, Reliant is located near three main airports — Dallas Fort Worth International Airport, Dallas Love Field Airport, and Alliance Airport — expanding our global reach and allowing our business to deliver comprehensive services for plastic fabrication to clients near and far.

Our international reputation lies in our design and manufacturing expertise. Reliant capably engineers and produces parts ranging from everyday plastic components and assemblies to carbon-infused thermoplastic components capable of replacing aluminum and metal parts. We help our partners achieve critical weight reductions.

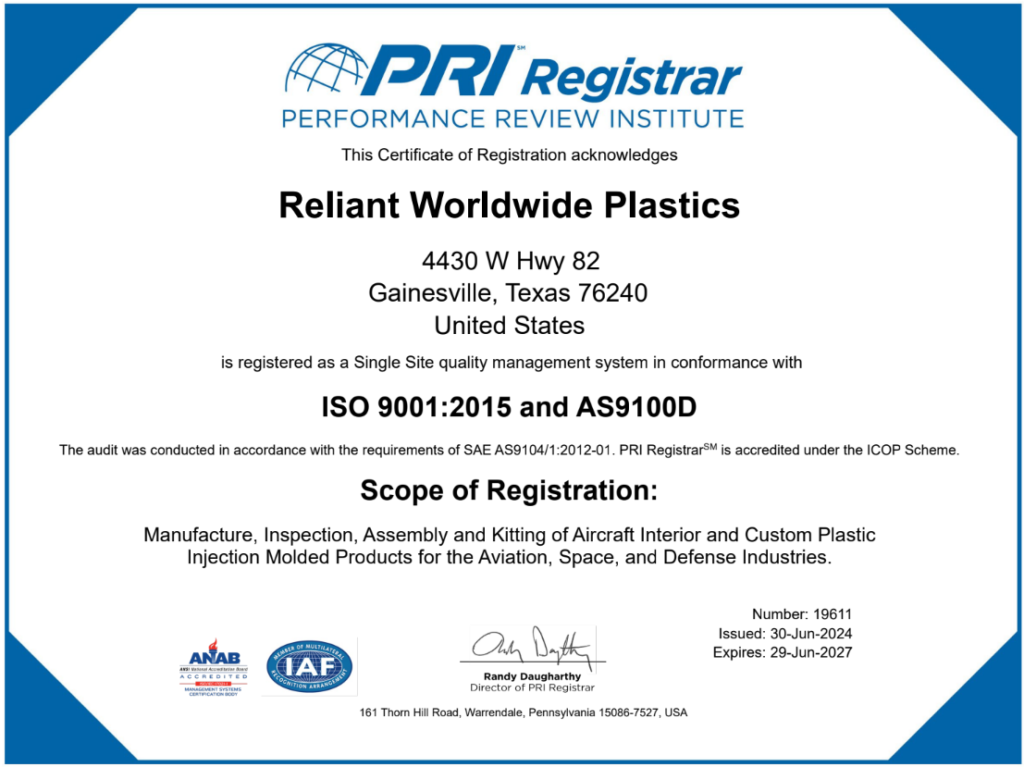

Reliant is ISO 9001:2015 + AS9100D Quality Management Systems certified, which goes beyond basic ISO standards to ensure extended product quality and safety.

COMPANY OVERVIEW

PEDIGREE

For more than half a century, Reliant has been providing injection molding to a number of different markets. In that time, we’ve seen remarkable changes in the plastic manufacturing landscape. New methods have emerged and computer technology has revolutionized design approaches, with breakthroughs continuing to this day.

As thermoplastic research blazes new ground and material options become more diverse than ever, manufacturers are required to adapt. Over the years, we have always stayed in sync with these changes and offered our clients’ the most updated and innovative capabilities aligned with a global economy.

Solutions designed and manufactured by Reliant are currently present on Airbus and Boeing platforms. Our skills enable us to serve industry partners with the highest-quality and tolerance conformity standards. Supporting projects in aerospace, automotive manufacturing, and the military and defense sectors means adhering to strict controls and well-documented processes. Reliant achieves excellence across the board, even in these challenging projects.

Reliant has a reputation for quality, reliability, and extensive capabilities at scale. Across more than 8,000 SKUs, we produce more than four million plastic parts annually. These numbers continue to grow as our facilities employ new and upgraded molding machines. From small, bespoke part production to massive scale for high demand, we flex to meet you at your level of need.

SECTORS WE SERVE

As a leader among plastic injection molding companies in the area, Reliant has established a positive reputation across many industries. Our design engineers and manufacturing skills extend to both consumer and commercial applications.

Industries we currently serve include:

Ask us today about how we can support manufacturing in your space.

SECONDARY OPERATIONS

Design and manufacturing are at the core of what we do, but our expertise and capability extend much further. We offer solutions to support our partners across diverse levels of need over many project types. Our secondary operations help streamline elements of your supply chain while centralizing more production steps into one consolidated process.

These secondary operations include:

Machining, Trimming, CNC Machining

Sub Assembly

Heat Stamping, Coating/Painting, Pad Printing

Sonic Welding

FACILITIES & TEAM

Reliant operates on a state-of-the-art, three-building campus spread across 13 acres. Our diverse team features a high level of experience, training, and knowledge across every department, from engineers to machine operators and everyone in between. As we continue to grow, so, too, do the capabilities of our facilities.

We operate an advanced lineup of cutting-edge molding machines ranging from 38 to 950 tons. Our equipment capabilities today facilitate faster changeovers, broader part availability, more rapid cycle times, and better sustainability during plastic fabrication.

Quality, Approvals, & Testing

Quality and timely delivery are our top priorities. We work diligently to provide our customers with the highest-quality parts when and where they need them. Key elements of our approach to delivering exceptional results include the following methods, qualifications, and certifications.

- ISO 9001:2015

- AS9100D

- Six Sigma and Lean Manufacturing Plant

- Statistical Process Control (SPC)

- Fabrication Inspection

- Advanced Product Quality Planning (APQP)

- FAA Approved Burn Lab

- Raw Resin Melt Flow Testing

- CMM Inspection of Critical Dimensions

Commitment to Exceptional Quality and Services

Reliant has provided plastic injection molding throughout the Dallas-Fort Worth area and beyond for decades. We work across various industries and flex every capability we have to meet the demands of our partners and the ever-changing market. Consistently adhering to the highest-quality standards, we are eager pursuants of the latest innovations.

With an expanded molding machine lineup and continued growth capabilities, we look forward to many more years of supporting projects at every scale. Reach out to discover how we can build a successful collaborative partnership with your team. Let’s achieve the right outcomes for your next project. Contact Reliant today.